Kyoto

[Event Report]Full-Scale Prototype Construction Experiment of a Free-Form Structure Using ABAF

Evaluating a New Construction Method Through a 1/15-Scale Form Inspired by Tachira Club

Researcher Sakai explores how flat structures can be elastically transformed into specific architectural curves, which is one of his key research themes.

In collaboration with the Gondo Laboratory, Department of Architecture at The University of Tokyo; the Kimura Laboratory, Graduate School of Design and Architecture at Nagoya City University; and Asahi Glass Building Wall Co., Ltd. (AGB), a demonstration experiment was conducted to explore the potential of applying this structural concept to architectural construction methods. While the form was inspired by the 1/15-scale geometry of the roof of the Tachira Club in Spain, the ABAF units and construction process were designed at a scale intended for real architectural applications, serving to validate the effectiveness of this new construction method.

This report provides an overview of the project. The pavilion was exhibited at “CAADRIA 2025 TOKYO”, a conference held at the University of Tokyo from March 22 to 29, 2025.

Recent advancements in computer-aided design (CAD) and structural optimization have made it increasingly feasible to design and realize complex freeform surfaces.

However, constructing such geometries remains challenging, particularly in fabricating, transporting, and reusing formwork.

This study proposes a new solution to these challenges through the use of a formwork system called Auxetic Bending-Active Formwork (ABAF). ABAF enables the formation of freeform surfaces with both positive and negative Gaussian curvature by elastically deforming flat grid structures on-site. This method allows the formwork to be shipped flat and reshaped on-site, making it reusable and more efficient for construction.

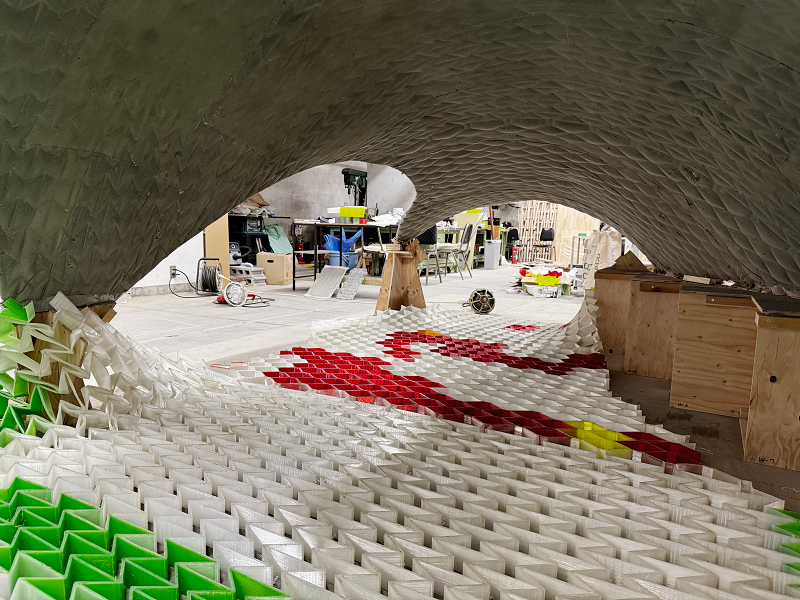

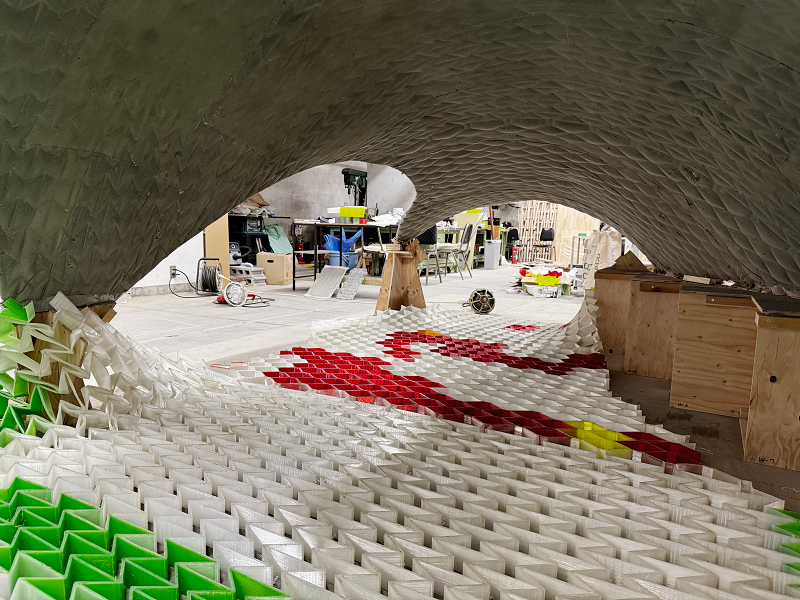

In the demonstration experiment, we created a 1/15-scale pavilion inspired by the roof geometry of the “Tachira Club”, originally designed by Spanish structural engineer Eduardo Torroja.

The construction process included the following steps:

- Construct a wooden base mold

- Install the ABAF system over the wooden base

- Cast Glass Fiber Reinforced Cement (GRC) over the ABAF

- Remove the ABAF units and wooden mold, after the GRC has cured

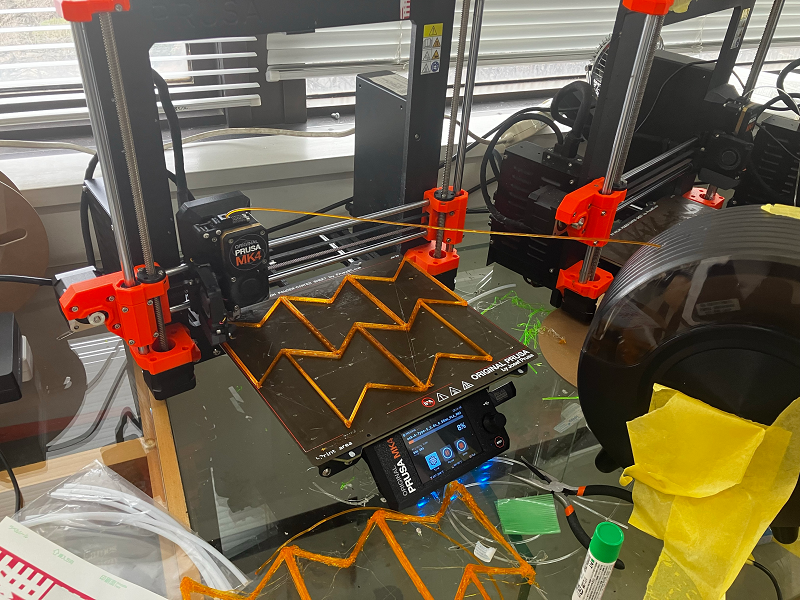

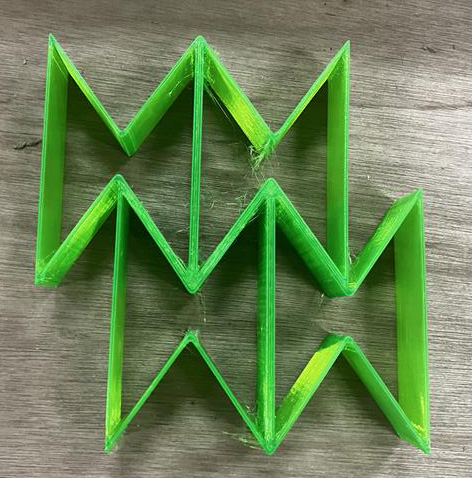

The ABAF units were fabricated using 3D printers at the University of Tokyo, Nagoya City University, and Sony Computer Science Laboratories. Each unit measures approximately 240 mm × 200 mm and consists of 4 to 6 grids.

To achieve the desired form, which transitions smoothly from convex areas to saddle-shaped curves, five primary types of grids were produced.

“To support this study, we developed a new algorithm for grid generation. If the grid size is too large, the GRC tends to sag, whereas if it’s too small, the 3D printing process becomes excessively time-consuming. We also had to consider factors like bendability and resistance to excessive deformation. After comprehensive evaluation, we settled on this final configuration”, explained Researcher Sakai.

These 3D-printed units were assembled into a single flat panel and placed on top of the wooden frame.

After GRC application and removal of both the ABAF and the wooden mold, the pavilion was completed.

The final dimensions of the pavilion were approximately 4 m × 2.6 m × 1.3 m.

Most of the construction process for this pavilion was carried out by students, and the structure was completed in approximately ten days. This demonstrates that even complex curved surfaces can be realized within a short amount of time and without highly specialized skills.

While the construction of freeform architectural structures typically demands advanced fabrication techniques and highly precise formwork, the ABAF system has the potential to significantly reduce such constraints.

Unlike conventional timber formwork, which is usually custom-made for a specific curve and discarded after being used once, the ABAF units are reusable and flexible. By rearranging the modular units, it is theoretically possible to produce a variety of curved surface geometries.

“Until now, our work had been limited to digital simulations or small-scale physical models that could fit in the palm of a hand. This was the first time we attempted to realize our structural concept at such a scale. With both uncertainty and excitement, it was deeply rewarding and meaningful to successfully construct the intended curved surface from a flat panel at this scale.

Completing the pavilion through this experiment and establishing a scale standard for the grid are major achievement that will inform future developments. Although the concept had been in preparation for about five years, seeing it finally take shape in the real world reignited my passion for creation”, says Researcher Sakai.

The construction of this pavilion took place during the CAADRIA2025 TOKYO conference held at the University of Tokyo, an event focused on computer-aided design in architecture, urban engineering, and information engineering across Asia.

*This research was supported by JSPS KAKENHI 24K01031.

Related Publications

Title:Auxetic Bending-Active Formwork System for Free-Form Continuum Shells

Authors : Nakayama K., Awaji H., Sakai Y., Yoshikawa R., Hayashi S., Gondo T., Kimura T.

Yusuke Sakai

Related News

The conference is an international meeting focused on information geometry, and Dr. Frank Nielsen served as a Co-Organizer, contributing to the organization and operation of the event.